Introduction: Beyond Tradition – How Die Casting Reshapes Automotive Performance

Imagine a vehicle that combines sports car acceleration, sedan-level fuel efficiency, and SUV durability. This isn't science fiction but the reality being achieved through automotive die casting technology. As a precision manufacturing process that injects molten metal into molds under high pressure, die casting is quietly transforming vehicle performance through its unique advantages.

1. Automotive Die Casting: The Key to Modern Vehicle Performance

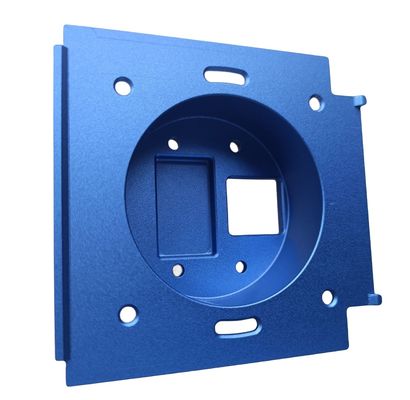

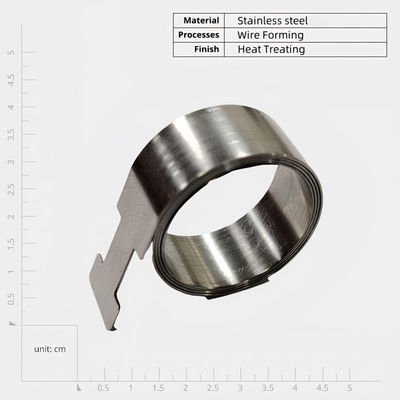

Die casting is a manufacturing process that injects molten metal (typically aluminum or zinc alloys) under high pressure into mold cavities. This technique produces complex, precise metal components essential for modern automobiles.

1.1 Process Fundamentals: Precision Under Pressure

The core of die casting lies in using high pressure to rapidly fill mold cavities with molten metal, which solidifies under pressure. Compared to traditional casting, die casting offers:

- High-pressure injection: Pressures ranging from several to hundreds of megapascals overcome surface tension and viscosity for complete mold filling.

- Rapid cooling: Water- or oil-cooled systems produce fine grain structures for enhanced strength.

- Automated production: Modern systems handle feeding, injection, cooling, and ejection for consistent quality.

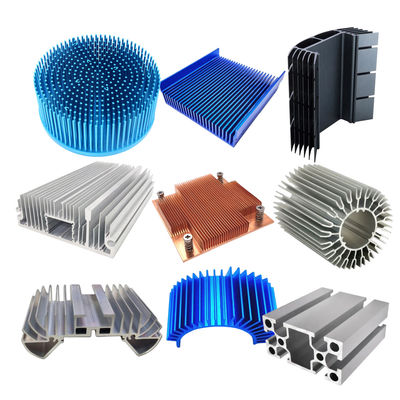

1.2 Material Selection: Aluminum vs. Zinc Alloys

Primary die casting materials each serve different automotive applications:

| Property |

Aluminum Alloys |

Zinc Alloys |

| Density (g/cm³) |

2.6-2.8 |

6.6-7.2 |

| Tensile Strength (MPa) |

150-350 |

200-400 |

| Melting Point (°C) |

550-700 |

380-420 |

| Applications |

Engine blocks, transmission housings, chassis components |

Interior parts, locks, handles |

1.3 Production Workflow: From Design to Finished Product

The die casting process involves:

- Mold design with simulation analysis

- Precision mold manufacturing

- Metal melting and composition adjustment

- Pressure-controlled injection

- Cooling and ejection

- Finishing processes

2. Performance Breakthroughs in Critical Components

Die casting enhances key automotive systems through weight reduction, strength improvements, and precision manufacturing.

2.1 Engine Blocks: Lightweight Meets High Performance

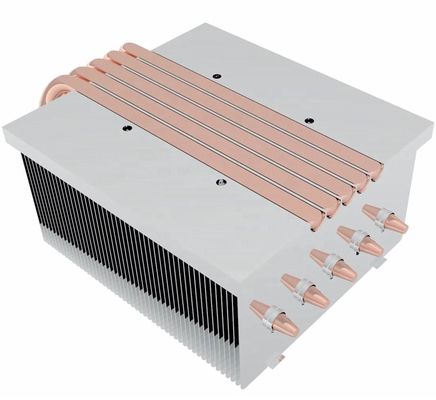

Aluminum die-cast engine blocks demonstrate 20-30% weight reduction versus cast iron, improving fuel efficiency by 5-10% and acceleration by 8-12%. BMW's B-series engines exemplify this through optimized cooling systems.

2.2 Transmission Housings: Power Transfer Efficiency

Die-cast aluminum housings reduce weight by 15-25% while improving heat dissipation (10-15%) and noise reduction (5-8%). ZF's 8HP transmission showcases these benefits through integrated oil channels.

2.3 Chassis Components: Handling and Comfort

Suspension components achieve 10-20% weight reduction with corresponding handling improvements. Tesla's Model S demonstrates how structural optimization enhances both performance and ride quality.

3. Five Core Advantages: Data-Backed Value Proposition

- Fuel Efficiency: 100kg weight reduction improves efficiency by 5-7%

- Performance: 8-12% power increase in aluminum-block engines

- Durability: 20-30% higher fatigue strength versus cast iron

- Cost Efficiency: 10-15% lower production costs with 20-30% faster cycles

- Design Flexibility: Complex geometries enable integrated cooling/oil channels

4. Emerging Trends in Die Casting Technology

4.1 High-Vacuum Die Casting

Vacuum environments reduce porosity for enhanced strength and corrosion resistance in critical components.

4.2 Semi-Solid Casting

Using partially solidified metal slurry improves material utilization and dimensional accuracy.

4.3 Integrated Casting

Consolidating multiple parts into single castings reduces weight while increasing structural integrity.

4.4 Advanced Materials

Emerging magnesium and titanium alloys address evolving performance requirements.

Conclusion: Die Casting's Transformative Role

Die casting technology enables production of high-performance, efficient, and durable vehicles. As innovations continue, this manufacturing process will increasingly influence automotive design and performance standards across the industry.

پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!  پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!